F2 Labs specializes in hazardous location product testing to ensure compliance with safety standards for explosive or flammable environments. We test to UL, CSA, IECEx, and ATEX requirements, helping you certify equipment for use in classified locations.

Intrinsic Safety (IS) Certification Evaluation – IS Design is a suitable approach to minimize the risk of ignition. The product as a whole must be evaluated. It is not enough to just have intrinsically safe components.

| Division | Presence of Hazardous Material |

| Division I |

ignitable concentrations of flammable gases, mist or vapors can exist under normal operating conditions

|

| Division II |

ignitable concentrations of flammable gases, mist or vapors are not likely to exist under normal operating conditions

|

Classes

The classes define the general nature of hazardous material in the surrounding atmosphere.

| Class | Hazardous Material in Surrounding Atmosphere |

| Class I |

Flammable gases, mist or vapors

|

| Class II |

Combustible dust

|

| Class III |

Ignitable fibers/flyings

|

Groups

The groups define the properties of the material in the surrounding atmosphere

- A – Acetylene

- B – Hydrogen

- C – Ethylene

- D – Propane

- E – Metal Dusts (Div. 1 only)

- F – Carbonaceous Dusts

- G – Non-Conductive Dusts (flour, grain, wood, plastic, etc.)

Zones

Zones are classified by the frequency and likeliness of ignitable concentrations of flammable gases, mist, vapor, or dust, fibers/flyings being present during normal operation of the product.

| Gases, Mists, & Vapors | Dust & Fibers/Flyings |

|---|---|

|

|

F2 Labs makes HazLoc testing simple. Experience the Difference.

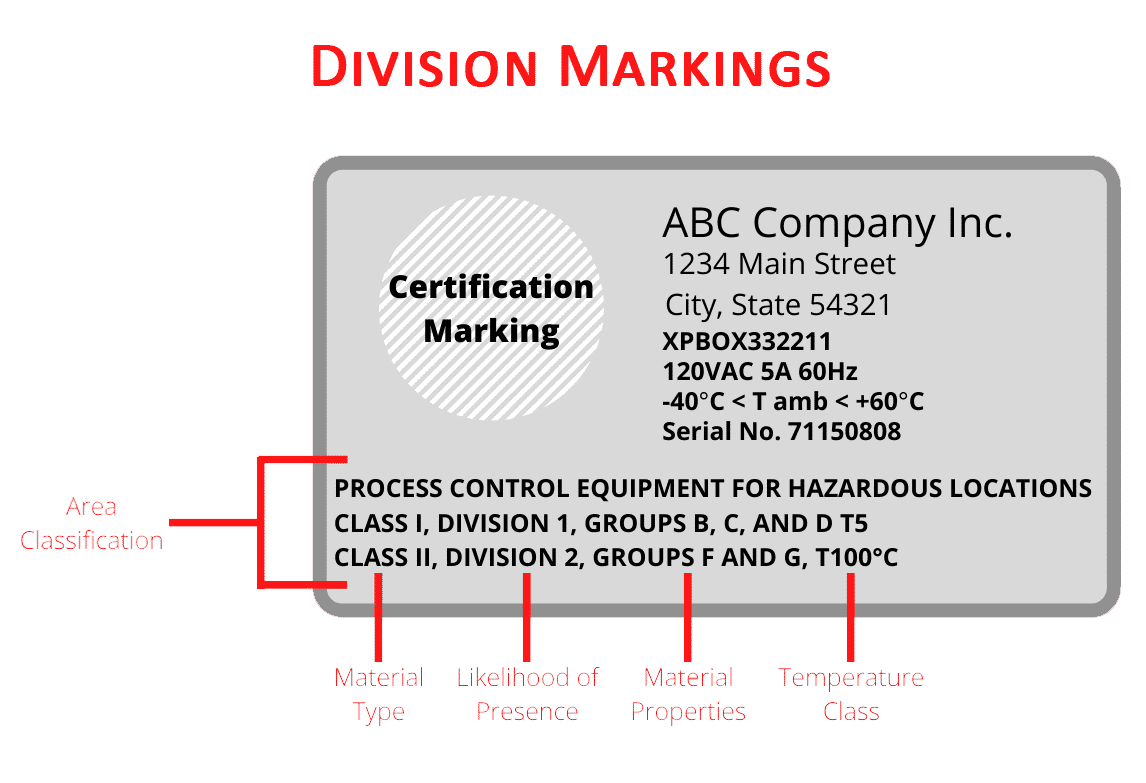

Below is a sample marking of a HazLoc label:

HazLoc standards:

IECEx Scheme

IECEx Scheme is an International approval scheme intended for equipment used in a potentially explosive atmosphere. These approvals help streamline the approval process when you intend to market your product internationally.

Countries Participating in the IECEx Scheme:

- Australia

- Hungary

- Romania

- Brazil

- India

- Russia

- Canada

- Italy

- Slovenia

- China

- Japan

- South Africa

- Croatia

- Korea

- Singapore

- Czech Republic

- Malaysia

- Sweden

- Denmark

- The Netherlands

- Switzerland

- Finland

- New Zealand

- Turkey

- France

- Norway

- United Kingdom

- Germany

- Poland

- U.S.A.