This is an often-asked question, “Do I need to translate the manual for the EU and what do I need to translate?”

The answer is everything that is needed top assemble, safely operate, maintain, and eventually dispose of the equipment must be translated.

The EU changed the requirements for translations with the 2008 New Legislative Framework (also called the 2008 NLF or just NLF). Several new CE marking Directives resulted from this including the below, though not an exhaustive list:

- Radio Equipment Directive 2014/53/EU

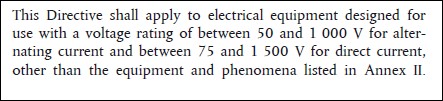

- Low Voltage Directive 2014/35/EU

- Electromagnetic Compatibility Directive 2014/30/EU

- ATEX Directive 2014/34/EU

- Pressure Equipment Directive 2014/68/EU

With these new Directives came more precise definitions of some terms and an alignment of requirements between the Directives. Prior to the 2008 NLF it was common to see differing requirements for the same document from Directive to Directive. For example, the formats for the declarations of conformity differed from one Directive to the next. The EU attempted to change that with the NLF and in addition to streamlining, they also tightened-up definitions, including the definitions and responsibilities of three classes of economic operators:

- Manufacturers

- Importers

- Distributors

This article focuses only on the translation requirements as concerns manufacturers. In plain English: if you are a manufacturer in the United States and you want to send a product to the EU then you will need to translate everything associated with it into the native language of every country you send it to.

Oftentimes I will break this down and document it for a customer who asks. Today I was asked again and decided to lift that information from the email and place it in a blog article here for future reference. In this case the customer has a product that is in the scope of the Radio Equipment Directive 2014/53/EU and asked how much material (instruction and operation manuals, maintenance manuals, quick start guides, etc.) needs to be translated.

Below is the response. Documented in the response is the requirement in the Radio Equipment Directive 2014/53/EU, the explanation of Article 10 (8) in the RED guide, and section 3.1.4. from EU Blue Guide to Product Rules, which is referenced in section 2.6 (j) from the RED guide.

See the RED 2014/53/EU, Article 10 (8.) –

Article 10

Obligations of manufacturers

8. Manufacturers shall ensure that the radio equipment is accompanied by instructions and safety information in a language which can be easily understood by consumers and other end-users, as determined by the Member State concerned. Instructions shall include the information required to use radio equipment in accordance with its intended use. Such information shall include, where applicable, a description of accessories and components, including software, which allow the radio equipment to operate as intended. Such instructions and safety information, as well as any labelling, shall be clear, understandable and intelligible. The following information shall also be included in the case of radio equipment intentionally emitting radio waves:

(a) frequency band(s) in which the radio equipment operates;

(b) maximum radio-frequency power transmitted in the frequency band(s) in which the radio equipment operates.

Next see the RED guide (attached), section 2.6 (j) –

j) Instructions

Article 10.8 of the RED requires manufacturers to accompany the equipment by instructions and safety information in a language which could be easily understood by consumers and other end- users, as determined by the Member State concerned. Furthermore, they shall be clear, understandable and intelligible. The Blue Guide, in Chapter 3.1.4, provides more details on how the instructions and safety information need to be provided. These instructions shall also include information required to use the radio equipment in accordance with its intended use. In particular, this information shall include, where applicable, a description of accessories and components, including software:

(1) have an influence on the conformity of the radio equipment, and

(2) are intended to be installed or changed by the user without the control of the manufacturer.

Accessories example:

? If the radio equipment is delivered without an antenna, then the technical features of the antenna that may be used in conjunction with the radio equipment shall be provided to the user. The user is responsible to operate the radio equipment and the accessories as intended and according to the description provided by the manufacturer. These technical features of the accessories shall therefore be mentioned in the instruction manual in order to enable the user to operate the compliant radio equipment. This information could be the generic characteristics of a given antenna type or a reference to a specific antenna(s) available on the market.

Software example:

? If the radio equipment has software (such as firmware, PC controlling software) that can affect its compliance with the Directive and the manufacturer intends and offers the possibility to the user to freely change it or modify it, then the software should be named in the instruction manual so that it is possible for the user to put a compliant radio equipment into operation. The manufacturer can decide the format of the description of this software as long as it can be identified.

On the other hand, if the radio equipment has software that can affect its compliance with the Directive but the manufacturer does not intend to allow the possibility for the user to change it or modify it, then no information has to be provided in the instruction manual. This is often the case of “software updates over the air” where the new software is installed under the full control of the manufacturer with no access by the user. In these cases the manufacturer ensures the installation of new software for which compliance with the Directive has been already assessed and reflected in the Technical Documentation.

With the objective of supporting authorities on their market surveillance activities, Article 10.8 of the RED requires manufacturers to accompany radio equipment which intentionally emits radio waves with information on the frequency bands and maximum output power with which the equipment is able to operate in the EU.

Manufacturers have different alternatives to fulfil these requirements. For example, any of the following options could be added to the instructions:

? the nominal frequency and transmitted power (radiated and/or conducted) used by the radio equipment, as reflected in the Technical Documentation,

or

? for radio equipment using standardized technologies, e.g. GSM/3G/LTE, indication of the frequency band in the way they are commonly well known (such as GSM 900, 1800). Where different power levels are possible, the nominal maximum power would be stated.

Next see section 3.1.4 from the Blue Guide:

As a general rule, when placing a product on the market the manufacturer must take all measures necessary to ensure that the manufacturing process assures compliance of the products and in particular:

4.accompany the product with instructions and safety information as required by the applicable Union harmonisation legislation, in a language easily understood by consumers and other end-users, as determined by the Member State concerned. Unless otherwise specified in specific legislation, instructions and safety information need to be provided, whether the product is intended for consumers or other end-users. This should include all the necessary information for the safe use of the product, to enable the consumer to assemble, install, operate, store, maintain, and dispose of the product. Instructions for assembly or installation should include the inventory parts and special skills or tools. Instructions on operation should include information for restriction of use, need for personal protective equipment, maintenance and cleaning or repair. It is for the manufacturer to determine the relevant information which should be included in the instructions and safety information for a particular product. Manufacturers have to look beyond what they consider the intended use of a product and place themselves in the position of the average user of a particular product and envisage in what way they would reasonably consider to use the product. Furthermore, a tool designed and intended to be used by professionals only might also be used by non- professionals, the design and instructions accompanied must take this possibility into account;

Our guidance and advice, based on the above and other similar documentation for other CE marking Directives, is that the manufacturer must make a translation of everything.

We can be contacted via this link. We can be reached by phone at

877-405-1580 and are here to help you.

F2 Labs is here to help.