We evaluate your device and keep it on autopilot, painlessly.

The RoHS Directive 2011/65/EU+(EU)2015/863 started life in 2002 as the RoHS Directive 2002/95/EC. It has changed over the years, adding substances and exemptions, and all affect the compliance of your device. Likewise, manufacturers and suppliers often change both the components and materials that comprise the parts you buy from them. And they do this with no obligation to alert you.

The REACH Regulation (EC) No 1907/2006 changes every six months. ECHA always adds substances to the restricted list. They never remove substances from the list which can make it excruciating for you and your staff. Presently there are 224 substances of very high concern, also called SVHC’s. That list is here: ECHA SVHC List and it will change again in either December 2022 or January 2023. Testing for REACH and RoHS is very expensive and it can cost thousands of dollars per part, depending upon what it is and how many materials make up the part. For example, a part made with plastic and metal can easily cost $3,000 to test. Just for one part. Now, multiply that against the number of parts a manufacturer like Molex, Murata, Vishay, or TE Connectivity produces. It is easy to see that this is a monumental task for these companies that never ends. You can imagine that once they clear a “list” of SVHC’s… right around the corner another, new list is published and the testing starts all over again. Then, add in that these companies likely have their own supply challenges and it is apparent that the RoHS and REACH status of these parts changes constantly.

What happens if the composition of a part changes?

Manufacturers can change how they make their parts. Suppliers can change who they buy a part from. In both cases they are not obligated to indicate to you, the electronic device manufacturer, what changes they made. In a worst-case example a supplier can sell you a machine screw made of RoHS and REACH compliant steel and use a descriptor and part number for that screw that is unique to their system. Let’s call it, “10 mm screw, pn 123456”. You could make orders for that screw over the years, always ordering their part number 123456, without knowing if that supplier is still using the same screw that was originally evaluated for RoHS and REACH compliance.

I routinely see examples of parts that were compliant at one point in time and then are not-compliant the next time the part is used in a build under review, and vice-versa. When this happens I see the part used in the new build — but I also see that the part is used in a build by a customer that submitted the device for review in the past. Below is an example.

TE Connectivity part number 87224-2

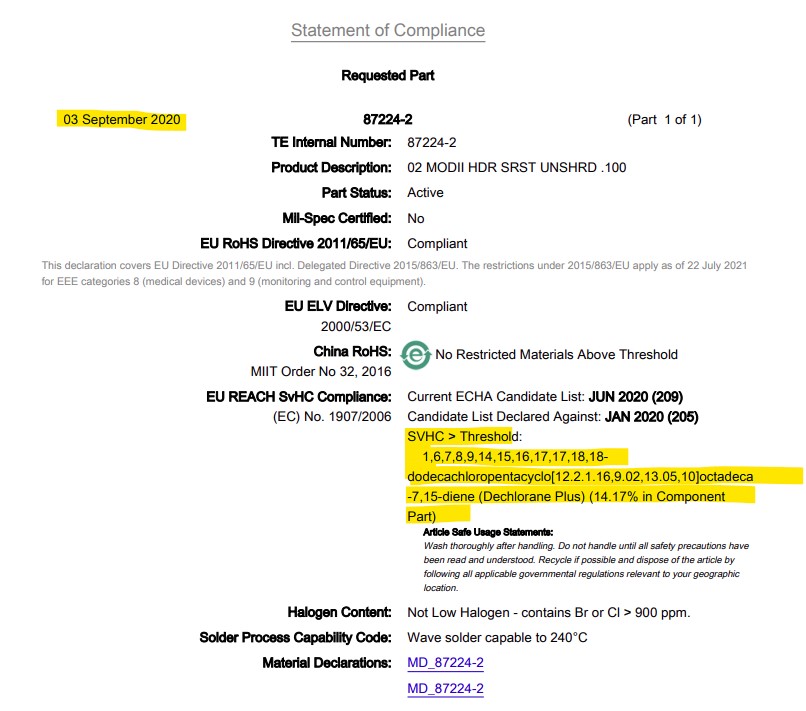

This part, number 87224-2, from TE Connectivity has been used in a few different projects from different manufacturers, first appearing in our system in 2020. 87224-2 was originally made with a REACH SVHC called 1, 6, 7, 8, 9, 14, 15, 16, 17, 18, 18-Dodecachloropentacyclo [12.2.1.16,9.02,13.05,10] octadeca-7, 15-diene (“Dechlorane Plus”). See a screenshot below from the Statement of Compliance produced by TE Connectivity in September 2020:

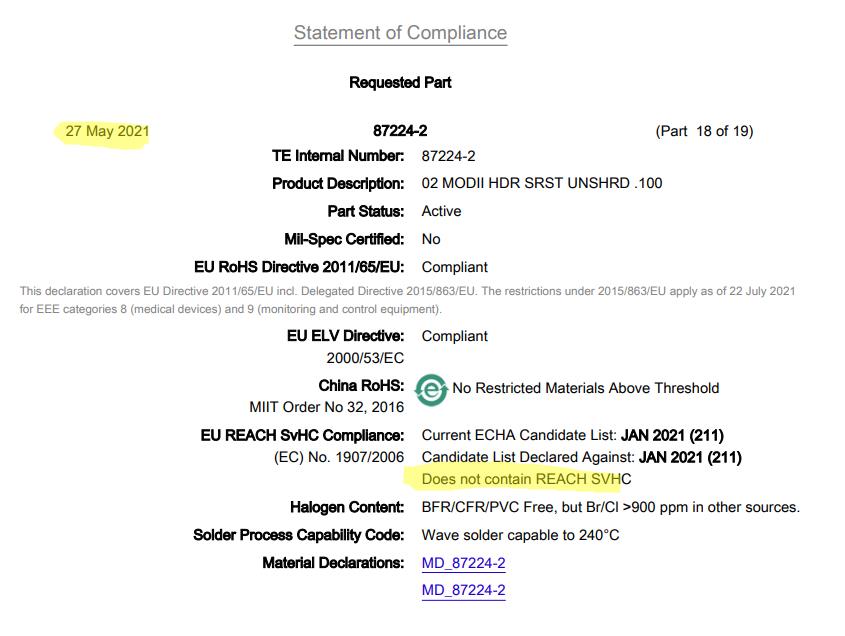

However, when this part was added to another assembly under review it was researched again in 2021 and we uncovered that TE Connectivity changed the build. As of May 27, 2021 the sole SVHC was eliminated from the build:

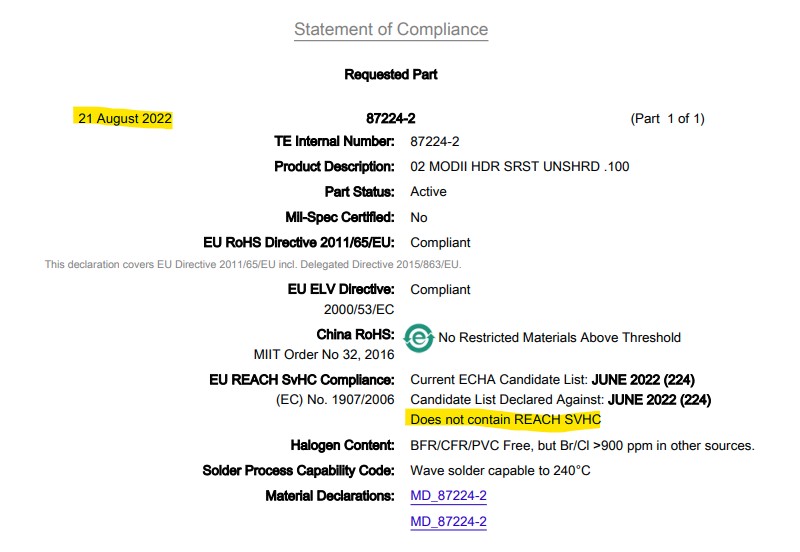

87224-2 is a popular part and crept into yet another build under review at F2 Labs this month. Reviewing the current data, we see that it has maintained its status as devoid of SVHC content:

Why is this important to you?

There is no one obligated at these companies to go through your past orders and tell you if a part you ordered a year ago now maintains the same RoHS and REACH status when you make a repeat order. You need to do this and it is your responsibility to alter your build(s) and or product documentation if there are restricted substances added into any of the parts used in your machine. No matter how insignificant. Even product labels made out of paper are in scope.

How can F2 Labs help you with this?

F2 Labs is a product safety and EMC test laboratory and we assist our clients with nearly all compliance requirements for global marketing and sales. We started offering RoHS services in 2014 and added REACH a few years later. We started these services because they are legal requirements and oftentimes our customers’ customer in the EU is unaware of these laws. We load your device in our system and can maintain the integrity of the build in an ongoing basis for products you make over and over. We can also perform a one-time RoHS and REACH evaluation for a custom product you are only making once.

Machinery, control panels, and medical devices are not excluded. RoHS and REACH apply to all equipment with electric function and that includes commercial, industrial, and medical equipment. REACH also applies to non-electric products. They are not restricted to consumer goods.

F2 Labs tracks down the EU RoHS and EU REACH (and we can do this for California Prop 65 and California RoHS also) status of each and every part, terminating with a report to you that indicates the compliance status. We can also tell you which of your suppliers responded and when, who ignored the request if that happens, and most importantly – the parts that are not compliant. The EU included teeth in these laws. They can fine you per device, make you pull it from the market, or even test it in the EU and then send the bill to you. You do not want to ignore these requirements, even if your customer in the EU did not mention them.

CONTACT F2 LABS FOR HELP, THIS IS WHAT WE DO.

Want to discuss your project with us?

You can contact us at this link. Our phone number is 877-405-1580 and we are here to help you.

F2 Labs is here to help.