MY SUGGESTIONS AFTER REVIEWING HUNDREDS OF PRODUCTS

F2 Labs assists our customers with compliance issues for many markets across the world. We test equipment in our labs for electrical and mechanical safety & EMC / radio compliance in our three US-based accredited laboratories. But, testing is only part of your compliance process. It means nothing if the rest of your obligations are not met. The minutia of a properly prepared EU declaration of conformity and a correct Technical File with the appropriate documentation are equally important. And RoHS.

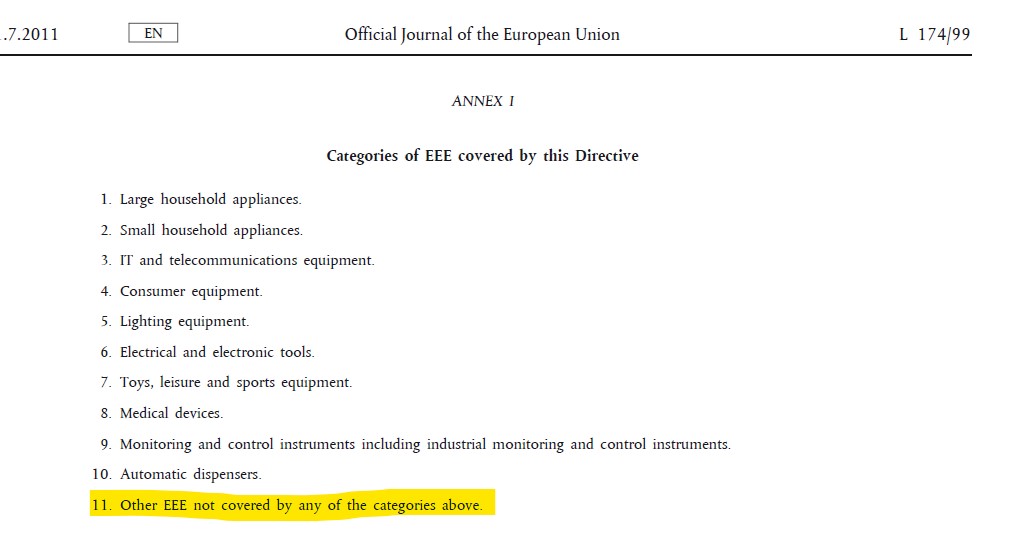

If your product has any electric function then chances are that it is in scope of the RoHS Directive 2011/65/EU, including its most important amendment; (EU)2015/863 – commonly called “RoHS 3” or “RoHS 10”. RoHS means restriction of hazardous substances and limits the amount of four heavy metals, two flame retardants, and four phthalates allowed in electrical products.

WHAT RoHS, RoHS 2, RoHS 3, AND RoHS 10 MEAN?

First, let’s define the terminology. RoHS 2002/95/EC was the original RoHS Directive and covered the original six substances (four heavy metals and two flame retardants). RoHS 2002/95/EC was not a CE marking Directive. It was largely ignored and RoHS 2002/95/EC was commonly referred to as “RoHS“.

Next, RoHS 2011/65/EU became effective in 2013 and brought some significant changes. Namely – it was required for CE marking and that includes required reference on the EU declaration of conformity. However, it’s applicability was phased-in and since many types of industrial and medical equipment were part of the phase-in process… it was also largely ignored until about 2017. RoHS 2011/65/EU is commonly referred to as “RoHS 2“.

Finally, many amendments have been added to RoHS 2011/65/EU and most of those deal with specific exemptions to the substance level restrictions. For example, a brass part may contain up to 4% lead content. (EU)2015/863 is the most important amendment and added four additional substances, the phthalates. These are chemicals used in plastics to make the plastic more flexible and soft. They are also dangerous to the human body. The additional phthalate restrictions were enforced starting in July 2019 and, by product category, fully effective on July 22, 2021. RoHS 2011/65/EU combined with (EU)2015/863 is alternately referred to as “RoHS 3” and “RoHS 10“. RoHS 3 because it effectively became the 3rd RoHS and RoHS 10 because it restricts ten substances. However, technically, it is just an amendment to RoHS 2011/65/EU. Therefore a claim of RoHS compliance or even a claim to only RoHS 2011/65/EU is a claim of compliance to RoHS requirements, including all applicable amendments.

RoHS COMPLIANCE – A LITTLE MORE DETAIL

We evaluate RoHS compliance for our customers’ products by researching every item on a specially prepared BOM (bill of materials). Every individual item must be included on the BOM and each of these parts are then evaluated for compliance. That includes non-electrical parts like bolts, screws, enclosure materials, plastic parts, labels, and even the paint or coating. This is because if your device is in scope of the RoHS Directive then each part in the build (except a few exceptions like packaging, non-electric consumables, and batteries) must individually comply with the substance level restrictions. Each piece individually.

For example, since lead (Pb) is restricted to 0.1% by weight then each individual piece of your device may not exceed 0.1%. It does not mean that you can use a piece of metal in your device that is 50% lead, but a tiny amount (less than 0.1% of the total weight of your device). For example – if you make a drill press that weighs 1,200 pounds and on the PCB you use a pin that weighs one gram comprised of 0.25% lead… you are not in compliance. 1 gram = 0.002205 pounds. 25% of 0.002205 pounds is 0.00055125. This equals 0.00046%, well below the 0.1% restriction level. But, the restriction level is part-by-part, not against the weight of the whole device. The logic for this is that if you have some substance in a part that is commonly touched, let’s say a button, not a pin buried in the machine on a board, there is a danger to the operator.

THE SUGGESTIONS FOR YOU

Now that we have set up the what and why let’s discuss the how. How do you make sure that by the time your BOM reaches my desk I will go through it and place a check mark next to each part and deliver a final, compliant Technical Report to EN 63000:2018 instead of a discrepancy report showing non-compliant parts?

Suggestion 1

Do not buy any electrical components that are not name-branded. Period. When I have to search for your fuse or cable on a site that also sells cheap socks, bird-food, and coffee filters – and delivers them in the same box – it is almost a certainty that there will be no RoHS compliance documentation, anywhere, for that part. That will stop your project cold.

Suggestion 2

Select for “RoHS compliance” when looking for parts on popular supplier sites like Digikey, Mouser, and Newark. We have no relationship or communication with these three companies.

Suggestion 3

No hardware manufacturer provides RoHS compliance information, that I have seen, like McMaster-Carr. The RoHS information must be collected individually but in my experience it is constantly updated on that company’s website. We have no relationship or communication with McMaster-Carr.

Suggestion 4

Using non-approved assemblies (like motors, power supplies, wireless modules, pumps, etc.) without suitable RoHS compliance will cost you, big. Think of this scenario… you pass all of the electrical and EMC/radio testing performed on your device but the motor in your product has no RoHS compliance information. At this point you are left with a few, equally terrible options:

- Pick a new motor, and repeat (at substantial cost) most or all of the compliance testing you just passed.

- Pay for a RoHS evaluation on the motor (which will be a completely new evaluation, with the same cost as an evaluation of your entire device… remember, a motor could have hundreds of parts).

- Pay for laboratory RoHS testing of the motor. This is not really an option… that could cost $50,000 or $75,000, or more.

Consider this regarding a non-RoHS compliant part that you have tested: you will have to then buy enough parts from that same lot to finish your build because you probably have no control over the materials used in another manufacturer’s device.

Suggestion 5

Specify RoHS compliance, through your purchasing department, for all parts used in any EU build. Catch it on the front-end and you will reduce costly delays on the back-end.

Suggestion 6

We supply very specific instructions for the preparation and submission of your BOM. Please read and follow these instructions. Please call me, directly, with any questions. My direct line is (301)368-2582 and I always answer my phone during business hours unless I am at lunch or I am talking to someone else

CONTACT F2 LABS FOR HELP, THIS IS WHAT WE DO.

Want to discuss your project with us?

You can contact us at this link. Our phone number is 877-405-1580 and we are here to help you.

F2 Labs is here to help.