UL 94 is a standard that measures, in a laboratory setting, the burn characteristics of plastic materials. The title of the standard itself is pretty descriptive: UL Standard for Safety for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

This standard is for testing plastic materials to ensure they meet the required resistance to burning for a specific application: typically for enclosures made out of plastic. Using this standard in a laboratory setting we are able to see and record the burning characteristics of a plastic to ensure it is suitable for its intended use. The tests tell us how quickly they self-extinguish because the amount of time that the plastic stays on fire is recorded and that is part of the criteria to determine the UL 94 rating applied to the material following the testing.

There are six tests that are outlined and defined in UL 94:

- Horizontal Burning Test: HB

- 50W (20 mm) Vertical Burning Test; V-0, V-1, or V-2

- 500 W (125 mm) Vertical Burning Test; 5VA or 5VB

- Thin Material Vertical Burning Test; VTM-0, VTM-1, or VTM-2

- Horizontal Burning Foamed Material Test; HBF, HF-1, or HF-2

F2 Labs hold ISO accreditation for all of UL 94 but by far the test we conduct the most is the 50W (20 mm) Vertical Burning Test (VB Test). We will discuss this testing in this article.

The VB Test is outlined in clause 8 of Ul 94 and instructions regarding the specifications of the test samples are detailed. Clause 8.3.1 identifies that the test samples, “…are to be cut from sheet material, or are to be cast or injection, compression, transfer molded to the necessary form.” Test samples need to be deburred and the edges smooth.

The VB Test samples must be 125 mm (plus or minus 5 mm) long by 13.0 mm (plus or minus 5 mm) wide. The sample can be no thinner than 0.025 mm – unless they distort while in the clamp during the test set-up. In that case the sample must be thicker. 13 mm is the maximum thickness. Additionally, intermediate thicknesses in 3.2 mm increments are also required in cases where the test results are inconsistent.

Pigmentation in plastic means that different materials or chemicals have been added to the plastic to change the color. This may mean that the burn characteristics are different. Therefore, each color of plastic used in your product, for which you want to claim a UL 94 rating, must be tested fully, according to the standard.

For the Vertical Burning Test, you will be required to submit twenty samples for testing. Ten of those samples will be placed in an environmental chamber for seven days prior to the testing and ten will be placed in a different chamber two days prior to the testing.

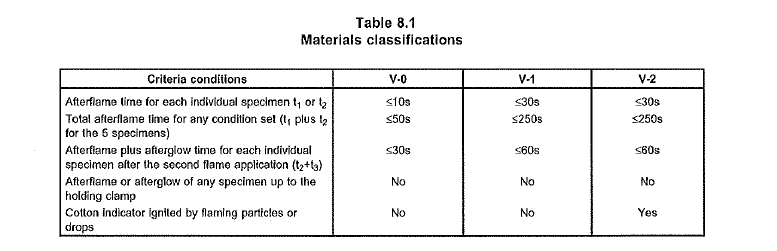

The VB Test then requires the burning of ten of the samples at a specific distance over a ball of cotton. The amount of time that the plastic remains on fire after the flame is removed from the plastic is measured. Whether the dripping particles are in flames and catch the cotton beneath on fire is also recorded. This data is then compared against Table 8.1 in UL 94, see below.

The classification of your material is made based upon these measurements.

Why 20 samples if we only burn ten? Good question. The standard requires 20 samples so that there are two batches of ten each. This is done in case there are wild differences in burning rates with the first batch of ten samples. If that happens there is a second batch with which to conduct testing.

Many times you can alleviate the need for UL 94 testing for the plastic in your product by specifying suitably approved plastic from your plastic vendor. To understand what you will need (which VB rating) you will need to evaluate the design of your product against the relevant safety standard applicable to your product.

F2 Labs is here to help. Have a question or a comment? We can be contacted via this link. We can be reached by phone at 877-405-1580 and are here to help you.