What is a Notified Body and what does it have to do with the Machinery Directive 2006/42/EC?

In most cases presented to us, absolutely nothing. I wanted to write this article because we are asked, from time to time, if we can offer a Notified Body certificate (more accurately called an EC type-examination certificate) for a machine.

A Notified Body is a company with a special status conferred upon it by an EU member nation, recognizing its technical competence in a specific aspect of compliance related to particular EU CE marking Directives, or a product category from a CE marking Directive.

A precise definition is offered in section 5.2.1. of the EU Blue Guide to Product Rules:

“Notified bodies are conformity assessment bodies which have been officially designated by their national authority to carry out the procedures for conformity assessment within the meaning of applicable Union harmonisation legislation when a third party is required. They are called ‘notified bodies’ under EU legislation.”

In the case of the Machinery Directive 2006/42/EC a Notified Body can only be involved for particular types of equipment. That equipment is listed in Annex IV:

ANNEX IV

Categories of machinery to which one of the procedures referred to in Article 12(3) and (4) must be applied

1. Circular saws (single- or multi-blade) for working with wood and material with similar physical characteristics or for working with meat and material with similar physical characteristics, of the following types:

1.1. sawing machinery with fixed blade(s) during cutting, having a fixed bed or support with manual feed of the workpiece or with a demountable power feed;

1.2. sawing machinery with fixed blade(s) during cutting, having a manually operated reciprocating saw-bench or carriage;

1.3 sawing machinery with fixed blade(s) during cutting, having a built-in mechanical feed device for the workpieces, with manual loading and/or unloading;

1.4. sawing machinery with movable blade(s) during cutting, having mechanical movement of the blade, with manual loading and/or unloading.

2. Hand-fed surface planing machinery for woodworking.

3. Thicknessers for one-side dressing having a built-in mechanical feed device, with manual loading and/or unloading for woodworking.

4. Band-saws with manual loading and/or unloading for working with wood and material with similar physical characteristics or for working with meat and material with similar physical characteristics, of the following types:

4.1. sawing machinery with fixed blade(s) during cutting, having a fixed or reciprocating-movement bed or support for the workpiece;

4.2. sawing machinery with blade(s) assembled on a carriage with reciprocating motion.

5. Combined machinery of the types referred to in points 1 to 4 and in point 7 for working with wood and material with similar physical characteristics.

6. Hand-fed tenoning machinery with several tool holders for woodworking.

7. Hand-fed vertical spindle moulding machinery for working with wood and material with similar physical characteristics.

8. Portable chainsaws for woodworking.

9. Presses, including press-brakes, for the cold working of metals, with manual loading and/or unloading, whose movable working parts may have a travel exceeding 6 mm and a speed exceeding 30 mm/s.

10. Injection or compression plastics-moulding machinery with manual loading or unloading.

11. Injection or compression rubber-moulding machinery with manual loading or unloading.

12. Machinery for underground working of the following types:

12.1. locomotives and brake-vans;

12.2. hydraulic-powered roof supports.

13. Manually loaded trucks for the collection of household refuse incorporating a compression mechanism.

14. Removable mechanical transmission devices including their guards.

15. Guards for removable mechanical transmission devices.

16. Vehicle servicing lifts.

17. Devices for the lifting of persons or of persons and goods involving a hazard of falling from a vertical height of more than three metres.

18. Portable cartridge-operated fixing and other impact machinery.

19. Protective devices designed to detect the presence of persons.

20. Power-operated interlocking movable guards designed to be used as safeguards in machinery referred to in points 9, 10 and 11.

21. Logic units to ensure safety functions.

22. Roll-over protective structures (ROPS).

23. Falling-object protective structures (FOPS).

See that the descriptor under the title “Annex IV” refers to Article 12 (3) and (4). It is now worthwhile to explain Article 12 from the Machinery Directive. Article 12 lays out the conformity assessment procedures for machinery. This means, in English, “this is what you have to do to put a CE marking on your machine.”

First, I want to show Article 12 (2.):

2. Where the machinery is not referred to in Annex IV, the manufacturer or his authorised representative shall apply the procedure for assessment of conformity with internal checks on the manufacture of machinery provided for in Annex VIII.

Article 12 (2) means that if your equipment is NOT indicated in the above Annex IV list then your only available procedure is to follow Annex VIII, which is below:

ANNEX VIII

Assessment of conformity with internal checks on the manufacture of machinery

1. This Annex describes the procedure by which the manufacturer or his authorised representative, who carries out the obligations laid down in points 2 and 3, ensures and declares that the machinery concerned satisfies the relevant requirements of this Directive.

2. For each representative type of the series in question, the manufacturer or his authorised representative shall draw up the technical file referred to in Annex VII, part A.

3. The manufacturer must take all measures necessary in order that the manufacturing process ensures compliance of the manufactured machinery with the technical file referred to in Annex VII, part A, and with the requirements of this Directive.

There is no mention of Notified Body intervention.

Next, see Article 12 (3.):

3. Where the machinery is referred to in Annex IV and

manufactured in accordance with the harmonised standards

referred to in Article 7(2), and provided that those standards

cover all of the relevant essential health and safety requirements,

the manufacturer or his authorised representative shall

apply one of the following procedures:

(a) the procedure for assessment of conformity with internal

checks on the manufacture of machinery, provided for in

Annex VIII;

(b) the EC type-examination procedure provided for in

Annex IX, plus the internal checks on the manufacture of

machinery provided for in Annex VIII, point 3;

(c) the full quality assurance procedure provided for in

Annex X.

We see that if your equipment is indicated in Annex IV then you have three options IF you used relevant harmonized standards to address the risks. The standards for the Machinery Directive are listed here: LINK. In that case (Article 12 (3.) (a)) you are able to follow the Annex VIII conformity assessment procedure, one of the three options, and not involve a Notified Body.

If, however, you did not use relevant EN standards to address the risks, then you must follow Article 12 (4):

4. Where the machinery is referred to in Annex IV and has not been manufactured in accordance with the harmonised standards referred to in Article 7(2), or only partly in accordance with such standards, or if the harmonised standards do not cover all the relevant essential health and safety requirements or if no harmonised standards exist for the machinery in question, the manufacturer or his authorised representative shall apply one of the following procedures:

(a) the EC type-examination procedure provided for in Annex IX, plus the internal checks on the manufacture of machinery provided for in Annex VIII, point 3;

(b) the full quality assurance procedure provided for in Annex X.

In the above case (Annex IV machine and either the manufacturer did not use harmonized standards or none were available) then the process is more complex, and requires technical intervention by a Notified Body.

Therefore, if your equipment is not indicated in the Annex IV list there is no way to involve a Notified Body for the Machinery Directive compliance of your equipment.

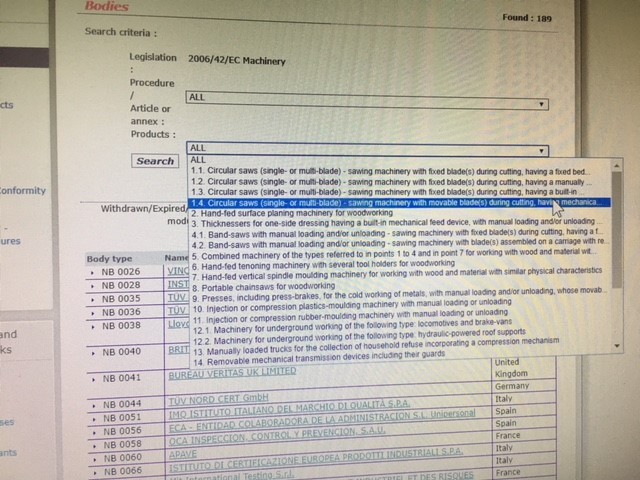

To put a period on this sentence, next, I direct the reader to the official European Commission list of Notified Bodies for the Machinery Directive, here.

Notice that in order to select a Notified Body you must first select the product category, and the product categories are arranged per the Annex IV list;

If your customer is mandating that your product comes with Notified Body approval under the Machinery Directive and your equipment is not listed in Annex IV, call us. We can help you. In every case that I have been involved in as relates to this issue we have helped the customer (and our customer’s customer) understand the obligations and put this issue to rest. It saves everybody time and money.

We can be contacted via this link. We can be reached by phone at 877-405-1580 and are here to help you.

F2 Labs is here to help.